Digital Supply Chain Solutions for Smarter Operations

Harness our team's industry knowledge and experience to implement digital solutions that automate processes and improve services.

Trusted Clients

Common Challenges Faced by Digital Supply Chain

Rising Costs and Supply Chain Challenges

Manufacturers face rising costs for materials and labor, pushing them to invest in digital technologies. Supply chain disruptions worsen the situation, driving up prices for goods from other regions.

Operational Efficiency Gap

Manufacturers are struggling to stay competitive globally because their efficiency and production rates are behind those of Asian competitors.

Adopting New Technologies

To succeed in the digital age, manufacturers need to fully adopt digital technologies and smart manufacturing. Using data throughout their operations can lead to significant growth and competitive advantages.

Embrace Digitalization

Manufacturers can benefit greatly by embracing digitalization. Adopting smart manufacturing practices helps them improve processes, foster innovation, and become industry leaders in a fast-changing market.

Boost your supply chain with real-time visibility, improved efficiency, and smarter, data-driven decisions

Real-Time Tracking

IoT devices monitor the location and condition of goods in transit, helping to prevent losses and ensuring timely delivery.

Inventory Management

Automated inventory tracking reduces the risk of stockouts or overstocking, optimizing storage and reducing costs.

Predictive Analytics

IoT data helps forecast demand, optimize logistics, and anticipate potential disruptions, improving overall supply chain resilience.

Automation

IoT enables automated processes, such as reordering supplies, adjusting production schedules, and managing warehouse operations.

Enhanced Communication

IoT devices facilitate seamless communication between different parts of the supply chain, ensuring that all stakeholders are informed and can respond quickly to changes.

Compliance and Reporting

IoT solutions ensure compliance with regulatory standards by automating data collection and reporting across the supply chain.

Expert support. Seamless scale. Sustainable success.

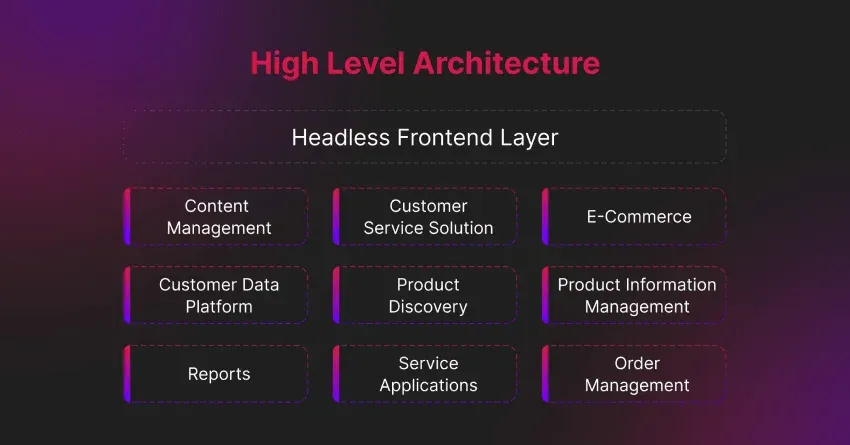

Digital Customer Portal - Architecture Overview

42Q: Our Digital Supply Chain Implementation Partner

42Q: Our Digital Supply Chain Implementation Partner

We are proud to collaborate with 42Q, a leader in cloud-based Manufacturing Execution Systems (MES), as our implementation partner for digital supply chain solutions. Their expertise in real-time visibility and seamless integration aligns perfectly with our mission to drive digital transformation. Together, we empower businesses to optimize operations, embrace Industry 4.0, and achieve scalable, future-ready supply chain solutions.

DataMiner: Our Partner in Digital Supply Chain Transformation

DataMiner: Our Partner in Digital Supply Chain Transformation

We’re thrilled to work alongside DataMiner, a trusted name in data management and analytics for supply chains. Their ability to integrate and analyze data in real time helps us offer smarter, more efficient solutions. Together, we’re making it easier for businesses to improve operations, make better decisions, and create more agile, data-driven supply chains.

Success Stories

Meraxis Optimizes Supply Chain Efficiency with Data Engineering

Learn how Intertec's data engineering solutions helped Meraxis, a global polymer leader, centralize its supply chain, automate processes, and generate 75% of its revenue through digital channels.

Book a Free Consultation

Trusted by leading businesses worldwide