The Rise of Smart Factories: Why AI Is No Longer Optional

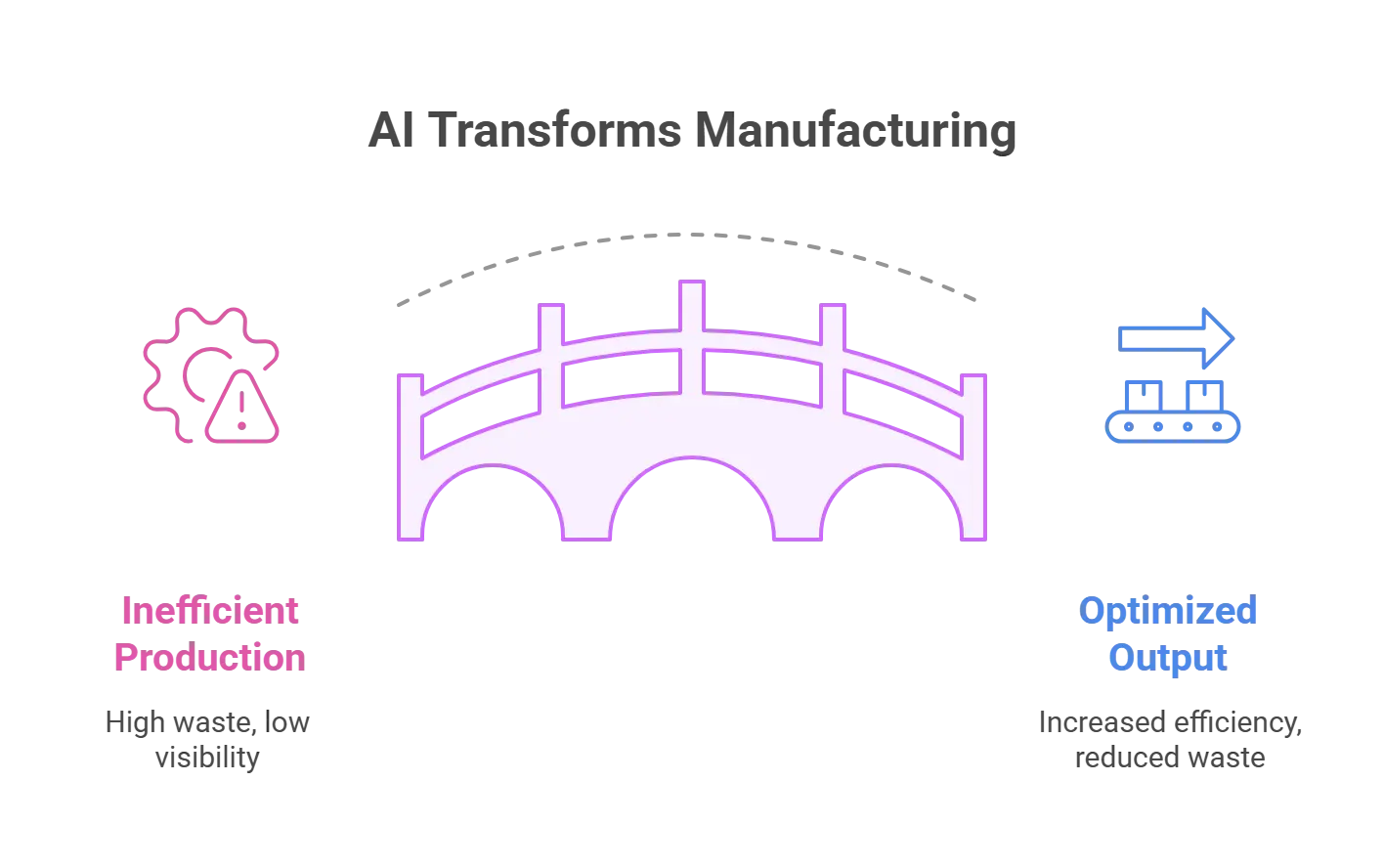

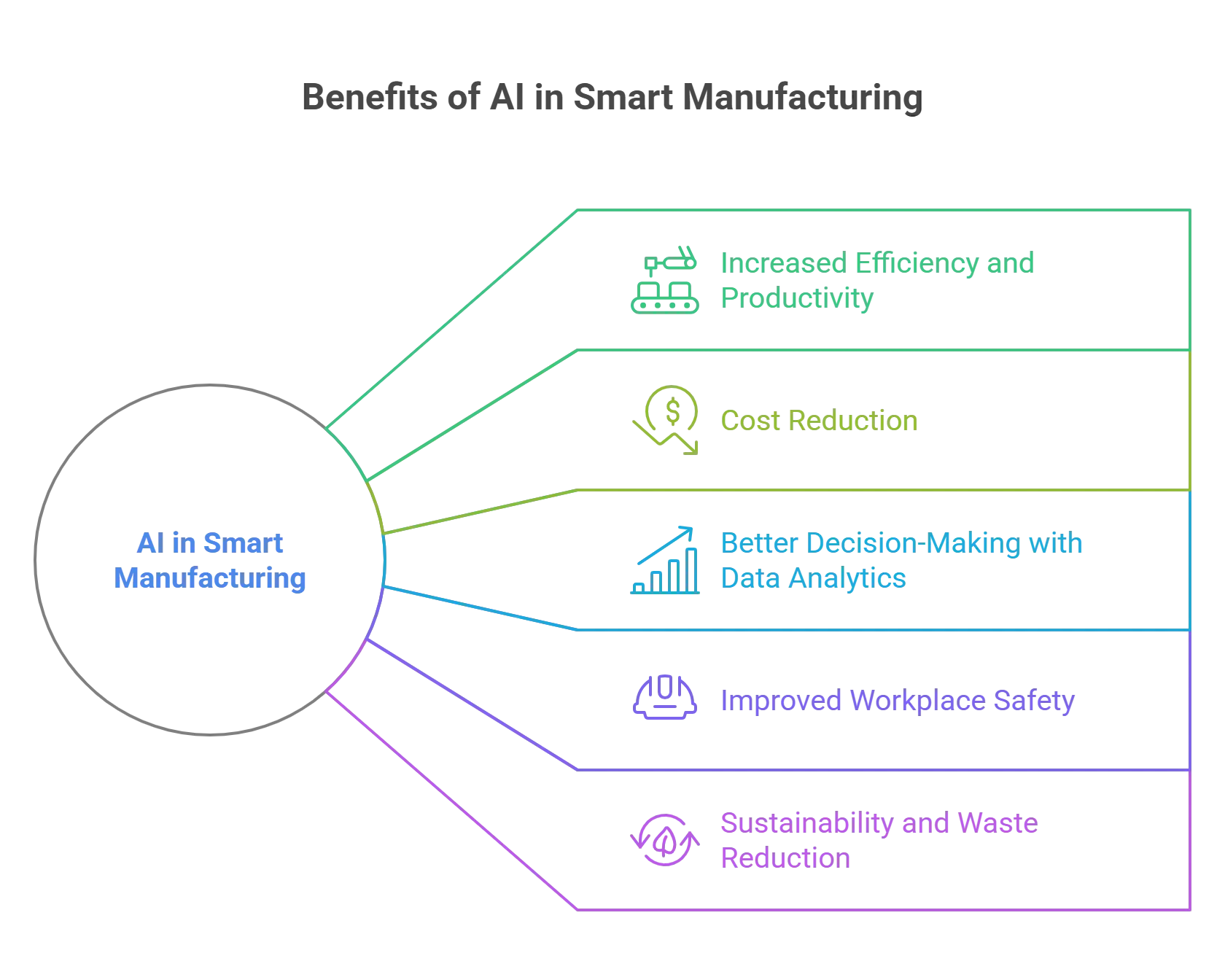

Traditional manufacturing processes relied on fixed schedules and reactive decisions. But today’s manufacturing sector faces too much complexity and variability for rigid systems to survive. Enter smart factories - digitally enabled environments where AI systems analyze sensor data and production data in real time to guide decisions.

Edge computing ensures latency-sensitive decisions - like halting a faulty production line - happen right next to the machine. Meanwhile, cloud computing supports heavy-duty AI models across facilities. This combination forms an integrated smart manufacturing system that continuously adjusts quality control, energy usage, and material handling - without replacing your existing equipment.

And the ROI? It’s already here. A recent Siemens study found that predictive maintenance powered by AI cut unplanned downtime by 50% and improved forecast accuracy by 85%. In an industry where customer demand shifts quickly and margins are tight, those improvements offer significant benefits.

Not to speak in theory, but from experience, check out our own case study on how we helped a client reduce their downtime by 40%.

Predictive Maintenance & Asset Management: From Guesswork to Guaranteed Uptime

Let’s face it- calendar-based maintenance is outdated. Either you're wasting time servicing perfectly healthy equipment, or you're reacting too late and paying the price.

AI in manufacturing changes that dynamic. Machine learning algorithms analyze data collection from sensors measuring vibration, pressure, temperature, and more. These AI models identify patterns that point to wear and tear - well before a failure occurs.

By moving to condition-based strategies, manufacturers can optimize maintenance schedules, reduce equipment failures, and improve asset management.

The result? Less downtime, fewer emergency part orders, and more time to focus on continuous improvement.

This approach not only increases efficiency but also empowers technicians to move away from repetitive tasks and toward high-impact work - one of the lesser-celebrated, yet crucial, changes AI brings to business operations.

Zero-Defect Ambition: AI-Powered Quality Control on the Shop Floor

In many manufacturing environments, quality control is still a manual - or rule-based - process. But with artificial intelligence entering the scene, that's rapidly changing.

Computer vision powered by deep learning inspects every product in real time. It compares high-resolution images against massive datasets of “good” products, enabling defect detection even when imperfections are too subtle for the human eye.

This isn’t just about product quality - it’s about speed and scale. AI-powered inspection systems identify inefficiencies and drive down return rates, warranty claims, and scrap. Especially in additive manufacturing, real-time monitoring detects layer issues early, so components aren’t wasted.

By using smart manufacturing technologies like synthetic data and transfer learning, even plants without millions of defect samples can deploy robust AI models quickly.

The result? Faster, smarter, and more scalable quality control that evolves as it learns from every production cycle.