Impact

The Challenge

With highly interconnected equipment and scattered data, the manufacturer struggled to identify early signs of failure. The lack of real-time monitoring led to high maintenance costs, productivity losses, and safety concerns.

The Result

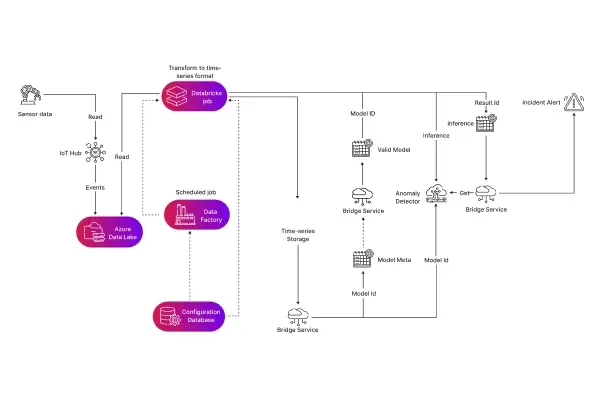

By integrating Azure’s AI ecosystem, Intertec enabled the client to predict failures before they occurred. The system now alerts technicians in advance, optimizes repair schedules, and provides decision-makers with live operational insights.

Key Features

- AI-Driven Failure Prediction

Machine learning models analyze sensor patterns to identify issues early and reduce unexpected breakdowns.

- Unified Data Infrastructure

Data lakes and pipelines centralize historical and real-time information for scalable analysis.

- Actionable Dashboards

Maintenance teams receive clear, visual alerts and recommendations via Power BI for immediate response.

- Cloud Flexibility

Azure’s platform supports rapid adaptation as equipment grows in complexity and data volume.